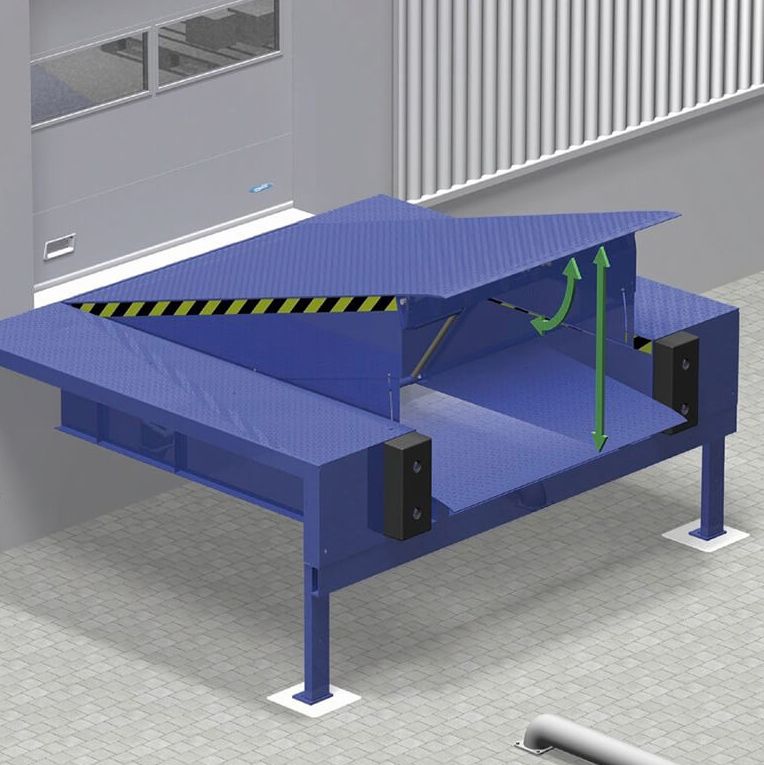

Loading dock levelers require proper usage and installation based on the manufacturer’s guidelines. Every dock leveler is different, they are created to handle a specific load capacity and performance. Problems generally occur when the operating guidelines are not followed and the person who operates the dock leveler has not been properly trained to operate the dock equipment.

This guide will help you avoid any dock leveler problem that you could have.

1. Get familiarized with the equipment.

– Read the manual. It is the manufacturer’s responsibility to give the manual that includes the dock leveler’s safety guide, the product features, the maintenance schedule, troubleshooting reference, component breakdown, warranty, and contact number where you can reach them in case there’s a problem with your dock leveler (also known as pit leveler and dock plate). Make sure to read and understand the manual carefully before operating them.

2. Select the right person to operate the dock leveler.

– The person assigned to operate the dock leveler must be trained properly.

– He/she should be physically fit to operate the device and must have a positive work attitude.

– He/she mustn’t operate the dock leveler under the influence of drugs or alcohol.

– He/she must read and understand the owner’s manual.

3. Practice safe operating precautions.

– Remember to always disconnect or remove the safety device when operating a vehicle restraint.

– Make sure that the warning signs are intact and never removed.

– Never operate the equipment when other unauthorized personnel is in the operating area.

– Make sure that the operating area is free from any foreign object that can cause an accident.

– Stay away from the dock leveler when a truck is approaching or leaving the loading dock area.

– Avoid placing hands or any part of the body towards the moving parts.

– Do not operate a damaged dock leveler, contact a reliable loading dock service company to check and repair the equipment.

– Always keep in mind, that the lips of the dock leveler should extend at least 4 inches onto the truck.

– Do not use the dock leveling equipment if the height of the truck is greater or lower.

– Avoid overloading the dock leveler.

– Don’t let any device or object left unattended on the dock leveler.

4. Make sure your dock leveler is ready before the maintenance.

– Arrange the leveler properly (in a vertical position with the lip extended).

– Maintenance props should be securely placed in the lowered upkeep standpoint.

5. Take proper safety measures during the dock leveler maintenance.

– Practice the “lockout/tag out” procedure. Turn off the electrical power, especially when welding the device. Lock the equipment with a locking device approved by OSHA. Take note that the only person who must have the access to the key is the person servicing the equipment. Barricades and warning signs must be placed in the workstation.

– Keep away from the dock leveler and the lip when working in front of the dock leveler.

6. Follow the manufacturer’s instructions.

– Inspect the roller track for correct form and must be clear from any unknown objects.

– Take away any device that may be banded to the dock leveler.

– Ensure that the lifting brackets and mounting structure are intact. Brackets should swivel deliberately to the mounting jolt.

– Install the carriage slowly.

– Installation of the carriage depends on its type; if it’s a manual side shift you can weld it on roller track stops. After that, you can now work on the electrical connections.

– Use chains and lifting equipment to carry the dock leveler. Choose a lifting device that can carry the capacity of your leveler.

7. Proper wiring and control panel installation

– Practice the“lockout/tag out” procedure. Before welding, the unit always remembers that ground wires and any source of electricity must be disconnected. A certified professional electrician is the only person authorized to do all the electrical work.

– Mount the push button at 48 inches height (distance from the dock floor to the basal portion of the control panel).

– Field electrical lines in the pit conjunction box and dock leveler electric cable should be interconnected.

8. Make sure placards are easy to read and are placed in designated areas.

– It is highly recommended that placards must be attached close to the control box by using a nylon tie. You can also post the placard to the wall, as close as possible to the dock leveler, at eye level.

9. When your dock levelers need troubleshooting do important preparations first.

– Raise the platform, turn off and disconnect all power sources.

– Every single fuse inside the control panel should be carefully checked.

– Replace the fuses that are broken immediately.

– Place a barricade and safety warnings on the work area.

10. All maintenance, service and replacement of parts should be documented.

– Written documentation will support that you are still liable for the product warranty.